Lamar Headworks Rehabilitation

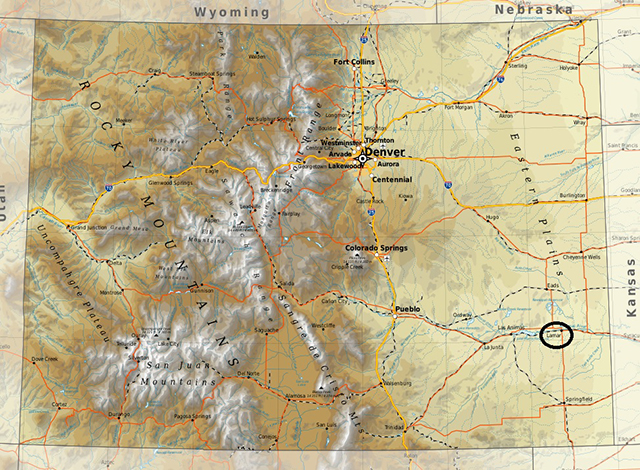

Located along the Arkansas River on Colorado’s southeastern prairie, the City of Lamar was founded in 1886 along the Sante Fe Trail. The rural community of 7,800 is at the heart of a vast agricultural region that is also heavily dependent on tourism and small business for its economic well being.

Like many rural communities, Lamar’s wastewater system is a mix of residential septic systems and a city managed sewerage system. Due to its location in the high prairie (fig 1), Lamar features predominantly flat terrain and therefore requires multiple lift stations to convey sewerage to a multi-stage lagoon system.

Lagoons are a popular method of wastewater treatment in rural communities around the world as they are among the simplest and least expensive systems to construct and maintain. These systems require more land than other wastewater treatment methods, but land is generally more widely available and less expensive in rural areas.

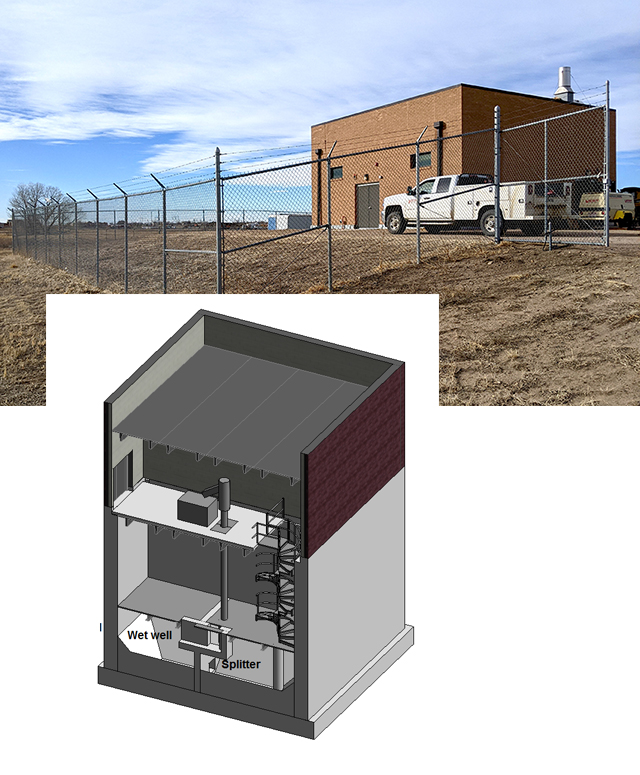

The Lamar wastewater system is composedof 56 miles (90 km) of collection lines ranging in size from 6 to 24 inches (15 to 61 cm),three lift stations on the east edge of the city, and one main pumping (headworks) station to pump (fig 2) wastewater into treatment lagoons (fig 3).

Extreme Corrosion

The city completed the headworks facility in 2010 (fig 4) to replace a preexisting lift station that had reached the end of its useful life. Unfortunately, the new headworks facility has experienced accelerated corrosion due to high levels of hydrogen sulfide (H2S) gas emitted from the slow moving sewage stream.Hydrogen sulfide gas is formed through the microbial breakdown of organic material in the absence of oxygen, known as anaerobic digestion. A complex bacterial process—known as microbial induced corrosion of concrete (MICC; sometimes shortened to MIC)—ultimately produces biogenic sulfuric acid that can steadily reduce the surface pH of concrete sewer system components to destructively low levels leading to rapid decay of the concrete elements themselves.

Such was the case with the Lamar headworks facility. In just a few years, the city was forced to address advanced corrosion in the young structure. The concrete wet well, where influent enters and large debris is filtered out, was losing concrete at a rapid rate. Microbial induced corrosion eroded the wet well interior so badly that up to two inches of concrete (fig 5) could be easily scraped off and even stainless steel components corroded away (fig 6).

New Approach Needed

“We recognized that the total solution for the Lamar system would require a new approachthat addressed both the resilience of thestructure and a reduction in extreme levels of hydrogen sulfide gas in the system,” notes Adam Teunissen, PE, a project manager for JVA Consulting Engineers, a Boulder, Colorado firm hired by Lamar to guide the repair of the corroded headworks facilty and attempt to counter the root cause of the corrosion.

JVA recommended that the headworks structure be restored using Xypex Megamix II with Bio-San, a resurfacing mortar formulated with Xypex crystalline waterproofing technology in combination with Bio-San bioactive mineral solids (fig 7). Megamix II with Bio-San provides chemical resistance to acids, sulfates, and chlorides, while also providing waterproofing, MIC resistance, and replacement of lost section thickness.

Xypex Bio-San mineral-based antimicrobial kills the Thiobacillus group of bacteria, the species responsible for microbial induced corrosion. Bio-San antimicrobial components are fixed in a mineral matrix that becomes an integral part of the concrete and cannot be washed off or wear out. These ingredients work indefinitely to destroy harmful bacteria at acellular level by releasing metallic ions that1) open holes in the bacteria’s cell membrane, and 2) attack and destroy the enzyme package necessary for the bacteria to reproduce. The cell is destroyed from the inside out.

Hydrodemolition was used to remove all unsound concrete from the wet well. Exposed rebar was cleaned and coated. Sacrificial anodes were attached in several areas (fig 8). Megamix II with Bio-San was then spray applied by applicators Advanced Shotcrete, based in Watkins, Colorado, and hand finished (fig 9).

According to Teunissen, “In the past, the go-to solution would have been some sort of coating like epoxy which, of course, would also require that the concrete be repaired first to provide a smooth base. That two-stage solution would have taken a lot of time and it is questionable if we could have gotten the wet well surface dry enough for a conventional coating like epoxy.”

Overcoming Below Grade Moisture

The wet well is located nearly 30 feet (9.1 m) below grade and subject to constant hydrostatic pressure from ground water. As a cementitious product, Xypex Megamix II with Bio-San provides excellent adhesion to moist concrete surfaces. “When you have backside water pressure, it can be a struggle to getthe surface dry enough for epoxy or other coatings,” Teunissen notes. “Megamix with Bio-San actually requires a moist surface to work, which is a big advantage. And, it seals the leaks that may be causing the wetness.”

The headworks repair project required that a bypass pumping system be used to redirect the normal sewage flow. “By using Megamix with Bio-San, we were able to reduce theneed for costly bypass pumping to the absolute minimum,” Teunissen says. “We probably saved at least two weeks in pump rental fees. We believe we saved both time and money by using Megamix with Bio-San.”

He continues: “We wanted to give the owner a different solution other than a coating system which did not prove effective the first time. When combined with the reduction in H2S we are seeing when we add Bioxide to the waste stream, we anticipate that the repair withMegamix with Bio-San will have a far greater lifespan.”

Teunissen notes that initial monitor readingsof H2S levels in the headworks facility hit nearly 1,000 parts per million (ppm), which actually broke some of the recording equipment. The Bioxide dispensing systems have been able to reduce the H2S gas levels to near zero in most cases.

Long-term Evaluation Planned

As part of the post-repair monitoring program, JVA will mount treated and untreated concrete cylinders inside the wet well and check them periodically to measure the effectiveness ofMegamix II with Bio-San. Independent studies of concrete treated with Bio-San have shown that treated samples had nine times less mass loss compared to untreated concrete. Bacterial concentration on the treated samples was minimal, even after 10 years of exposure.Xypex Bio-San C500 admixture was also used in the Lamar headworks restoration project. Several cubic yards of Bio-San C500 treated concrete were used to pour a new splitter box and fill a space that was determined to be at risk for future corrosion.

Bio-San Admix

Like Megamix II with Bio-San, the dual-protection Xypex Bio-San C500 also combines crystalline waterproofing with a mineral-based antimicrobial that kills the Thiobacillus group of bacteria species responsible for MIC. Xypex admix provides concrete precasters and ready-mix producers with a single, convenient product that can be added to any project or product that requires a high level of corrosion resistance, waterproofing and antimicrobial protection. Bio-San antimicrobial components are fixed in a mineral matrix that becomes an integral part of the concrete and cannot be washed off or wear out like conventional coatings.

JVA has specified Xypex crystalline waterproofing products—with and without Bio-San—for many past and ongoing projects, including all of the water-holding structures for a large public water park, a water tank for a local manufacturer, and several other wastewater treatment plants in Colorado.

“There are many, many situations where Xypex crystalline waterproofing, with and without Bio-San, is the right solution,” says Teunissen. “The Lamar headworks was a new structure that failed in just a few years. It was probably the worst corrosion rate I’ve seen in my career. We believe we have an excellent chance to succeed with the strategy we’ve chosen, combining Megamix II with Bio-San for surface restoration and H2S reduction with Bioxide (fig 10).